Machine shops, fabricators, and other metalworking shops often own both a circular cold saw and either a horizontal or vertical bandsaw. But if budgetary considerations cause a manufacturer to choose between the two, which of these saws will be a better fit for a specific type of work and fill the need for productivity and higher quality?

While cold saws and band saws each come with a set of advantages, the differences between the two sawing processes tend to favor the cold saw. And depending on your application, choosing a cold saw over a bandsaw can increase your productivity and allow you to attract a wider variety of customers.

Here is what you need to consider:

Cold saws provide consistent cut length accuracy

The circular cold sawing process produces a square face and part-length accuracy of +/- 0.005" or closer. The bandsaw blade's flexible nature allows it to drift throughout the cut, resulting in a much less accurate cut.

If you are looking to cut up material that will be machined later, a bandsaw will work adequately, but if your operation requires parts to leave the saw without further secondary operations, the cold saw is the better option.

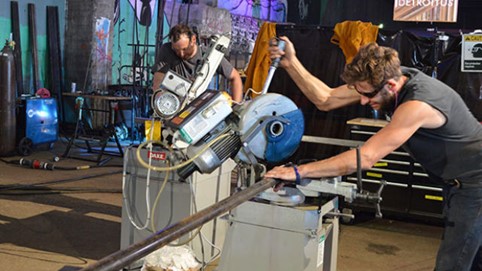

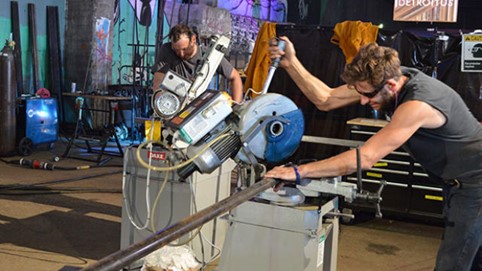

The hard-working Dake Technics 350A Semi-Automatic Cold Saw

Photo Credit: Dake Corp.

The cold saw finish is superior

Part finish and accuracy go hand-in-hand, and the cold saw will give you a square, accurate cut with a milled-like finish. Accuracy, squared cuts, and an excellent finish result in tight joints requiring no additional machining or "clean-up" cuts. These advantages become even more essential when secondary applications, such as welding, follow the sawing operations.

Cold saws are appropriate for all types of materials

All grades of steel, including stainless and high-carbon, work well with cold saws. They are ideal for thin-walled tubing, entering and exiting the material without generating excess heat, and producing a high-quality cut that requires no finishing operations.

Cold saws can run at lower RPMs for cutting aluminum, brass, copper, and other non-ferrous materials. And they are designed to cut a variety of steels successfully.

The cold saw has the edge when it comes to efficiency

Although the initial price of a cold saw blade would likely be higher than a bandsaw blade, you need to factor in that the cold saw blade can be re-sharpened, while the bandsaw blade must be discarded when it can no longer cut.

The re-sharpening benefit of a cold saw blade could be substantial cost savings, but there is another one: the downtime for a cold saw blade change would be much less than for a bandsaw blade change.

A recently resharpened carbide-tipped circular saw blade

Photo Credit: Universal Tool Sharpening

Choose a cold saw under the following circumstances

Pick the circular cold saw over a bandsaw if your shop:

- Cuts materials that aren't extremely large: cold saws are usually limited in diameter to 6" and under

- Does a lot of miter cutting

- It needs to have finishes that are clean, square, and accurate without using secondary operations

- Needs to avoid heating material or creating burrs on cut edges

- Is willing to pay more upfront but receive a higher return on investment (ROI)

Choose from automatic, semi-automatic, and manual cold saws

Investigate the models of Dake heavy-duty cold saws with choices among automatic, semi-automatic, and manual models. Each of them features 45-degree rotation for clean and accurate miter cuts, along with a coolant pump with flow control adjustment.

To find out more, fill out our contact form, call us at 1-800-937-3253, or email us.

-1.jpg?width=1200&height=525&name=DAKE003_%20Logos_Red%20(002)-1.jpg)