Very few manufacturers would argue against the importance of breaking in a bandsaw blade, but many of those that agree it should be done are skipping this critical step themselves. It might be that some of them are concerned that the break-in process is too time-consuming and hinders productivity. Others may think that breaking in a bandsaw blade is unnecessary.

Whatever the rationale, this integral part of a sawing operation is skipped all too often. And in today's competitive manufacturing environment, if adequately breaking in a bandsaw blade could give your company an advantage, why would you not do it?

Here is why you should and how to do it:

The blade design is not the only factor in determining blade life and quality of cuts.

If you want an efficient sawing operation with maximum productivity, you must keep your saws running. When your blades break or wear prematurely, the downtime for changing them is expensive. That is why metalworking and fabrication shops are continuously searching for ways to minimize downtime while delivering high-quality cuts.

Successful manufacturers understand that cost-per-cut is what matters most. A bandsaw blade that lasts longer and maintains quality cuts minimizes the cost-per-cut and results in increased productivity. But when these shops ensure that the bandsaw is well-maintained and the operator uses the manufacturer's speed and feed settings, there is often one more crucial step that they miss: breaking-in the blade.

What does breaking-in a blade do?

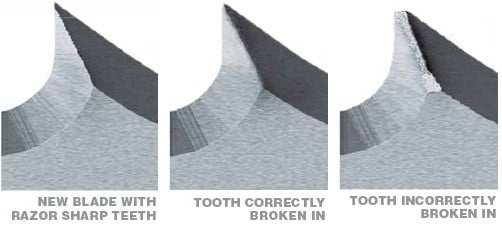

Because the teeth on a fresh bandsaw blade have sharp edges, they are more easily chipped or broken—unless they are broken in properly. Think about a newly sharpened pencil: the sharp point often breaks off, leaving you with an uneven point that doesn't write clearly.

By slowly increasing the feed pressure during break-in, the tooth's sharp edge is honed evenly, and a slight radius replaces the sharp leading edge of the tooth. The radius shears the chip from the material swiftly and provides support to the tooth tip.

After the teeth are broken-in properly, the blade will cut faster, straighter, and last longer than a blade that has not been broken-in correctly. The break-in process ensures that you get the highest productivity from your bandsaws (see the illustration below).

Photo Credit: L.S. Starrett Company

The break-in process

The procedure for breaking-in a bandsaw blade will depend on the material you will be cutting. However, no matter what the material, run the saw at the standard surface feet per minute.

Suppose you break-in the blade on softer materials, such as mild steel and aluminum. Back off on the feed pressure to half the regular cutting rate for the first 50 to 100 square inches. After that, gradually increase the feed pressure to 100 percent.

For harder materials--Inconel, tool steels, and stainless steels--adjust the feed pressure to 75 percent of the regular cutting rate for 25 to 75 square inches. Gradually increase the cutting rate to 100 percent, not creating vibrations caused by increasing the pressure too quickly.

While each blade manufacturer might have a preferred method for blade break-in, they will likely share the principles above.

Break-in your blades on heavy-duty bandsaws

Dake offers heavy-duty, American-made bandsaws featuring a dual cast head frame for large-capacity cutting. A three-point suspension, adjustable eccentric roller blade guides, centralized controls, four-speed drive, and 45-degree swivel vise jaws add up to the high-quality performance and maximum productivity.

The Model JH10W3 Heavy-Duty Horizontal Bandsaw (Photo Credit: Dake Corp.)

Check out the models of Dake horizontal and vertical bandsaws. Do you have questions? To get answers, fill out our contact form, call us at 1-800-937-3253, or email us.

-1.jpg?width=1200&height=525&name=DAKE003_%20Logos_Red%20(002)-1.jpg)