Horizontal bandsaws are essential machines in most fabrication and machine shops. And if you're designing a metalworking shop for your workshop or garage, this piece of equipment should be high on your list of purchases.

While they don't get the notoriety of mills, lathes, hydraulic presses, and all the high-tech CNC machine tools, without a horizontal bandsaw to cut material to size, these impressive machines wouldn't have a workpiece that fits on their table or in their chuck.

So, even though they will never hold center stage in most manufacturing shops, horizontal bandsaws will support your operations and help you achieve maximum productivity.

How does the horizontal bandsaw work?

For those new to metalworking machinery, the horizontal bandsaw is used primarily to cut metal into correct lengths with the straightest edge possible. The design of the machine and the strength of the blade allow for working with heavier metals within the dimensional capacity of the saw.

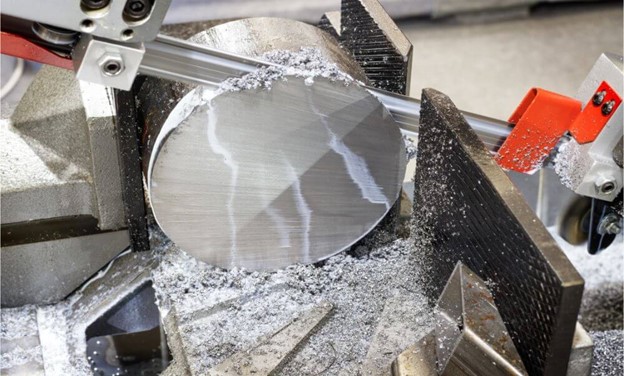

Horizontal bandsaw cutting through a large piece of round metal.

(Picture Credit: Welding Insider)

As shown in the picture above, the horizontal band saw holds the workpiece securely in a vise as the blade moves through it. A motor and hydraulic system raises and lowers the arm and controls the feed pressure of the cut, during which the operator's hands are safely away from the moving blade. After the cut is finished, an automatic switch turns off the blade, adding another safety feature.

Using a horizontal bandsaw in your shop

Horizontal bandsaws are relatively safe and straightforward to use. They provide consistent cuts in most types of metals as long as you follow a few rules:

- Select the right blade for the job contingent on the type and size of the material you're cutting.

- Set the saw's vise to the correct angle. Some saws have a movable arm to create miter cuts. Check out the Dake Model SE-810 Dual Miter Saw in action.

Dake's Dual Mitering Saw has a semi-automatic down feed and

a built-in mitering gauge to ensure accurate angle cuts

- Place the material into the vise, and tighten it enough to hold the stock securely.

- Select your blade speed depending on the type of material.

- Move the saw's arm down to within about a quarter-inch of the material, turn on the saw, and set the power feed to its lowest setting. After the cut starts, you can adjust the feed to add more pressure to the cut.

- The machine will turn itself off when the cut is entirely through the workpiece, and you can remove it.

The horizontal bandsaw should be in your workshop or your business

If you're setting up a new workshop, a horizontal bandsaw should be on your equipment wish list. If you already have a workshop, several Dake models from which to choose will take up little, if any, floor space. The Benchtop Horizontal Mitering Bandsaw (shown below) has many of the larger floor models' features.

Benchtop Horizontal Mitering Bandsaw from Dake

And if you have any other questions about horizontal bandsaws (or anything else, for that matter), talk to one of the Dake professionals.

Fill out our contact form, call us at 1-800-937-3253, or email us.

-1.jpg?width=1200&height=525&name=DAKE003_%20Logos_Red%20(002)-1.jpg)