In the recent decades, attending college has been the stamp of approval for many young people entering the job force.

However, with the influx of college graduates comes a highly competitive job market. Fewer young people have had their eyes set on a skilled-trades job than ever before, and that’s where the demand is.

Manufacturing jobs in metalworking are quite lucrative these days, and fresh talent is always needed. In this post, we will explore the various career paths you can take with metalworking skills.

A Skill Rooted in Tradition

Metalworking goes back to 6,000 BCE when the very first blacksmiths began smelting copper. Since then, the art of metalworking has transformed enormously.

From blacksmiths to jewelers and founders to machinists, there are numerous career paths one might take in today’s world with metalworking skills.

You can even get a degree along with those metalworking skills to become an engineer. However, having a formal education is not necessary to pursue a career in metalworking.

#1 - Production Machinist

One of the most popular metalworking jobs in 2020 is a production machinist. This is a tradesperson who has the ability to use hand tools and machines to create works of metal. Often, these abilities can overlap with over materials such as wood and acrylic plastic as well.

A production machinist may also take on the role of a CNC router operator or programmer. The duties of the CNC router operator include cleaning and maintaining the machine as well as changing the cutting tools, feeding the material through the machine, and quality assurance.

The CNC router programmer duties may include designing and customizing files on the CNC software to be imported to the machine.

#2 - Quality Assurance Inspector

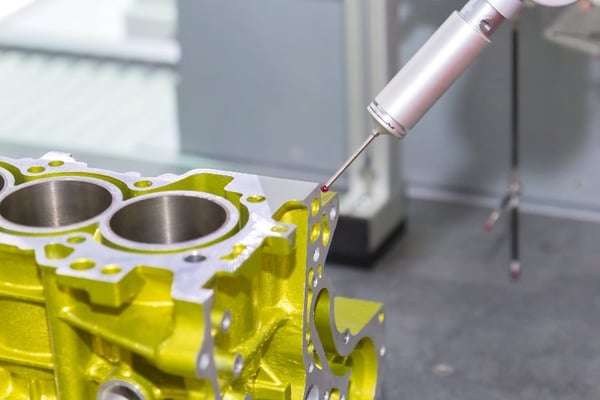

For those who have an education in quality management systems and also have an interest in metalworking, becoming a quality assurance inspector would be a lucrative career path. The main focus of this job is to prevent defects and find any that have already occurred.

This can apply to a broad range of things including welding quality, machining quality, production quality, and even the quality of the chemical and physical traits of metal. As a quality assurance inspector, you can become certified in any of these categories.

Quality assurance for machines is very important to the bottom line. If a machine is out of commission, that is money down the drain. Luckily, our machines here at Dake are built to last. Quality assurance inspectors love our models.

Vintage arbor presses are still in use today and very rarely require replacement parts. However, if the occasion does arise and an inspector wants a particular part replaced we manufacture that part quickly and have it shipped to the appropriate destination.

#3 - Mechanical Engineer

To become a mechanical engineer, you must first learn about the core principles of engineering physics, mathematics, design, and mechanical systems. These subjects include electricity, thermodynamics, analytical dynamic, structural analysis, mechanics, and materials science.

The mechanical engineering field was birthed during the Industrial Revolution, and it has grown to include a broad spectrum of engineering spaces such as civil engineering, electrical engineering, manufacturing, aerospace, and many more.

A Bachelor’s degree is required in order to get started on this career path, and it can take you to many different places. You could even design the next generation of CNC routers.

#4 - Sales Representative

If you enjoy meeting new people on a daily basis, perhaps becoming a sales representative for a metalworking company would be a good path to follow. There are generally no degree requirements for sale reps, but training and certification in customer service can go a long way.

Companies that manufacture metalworking machines are almost always looking for the next rockstar sales rep to move their equipment and send their profits soaring.

#5 - Metal Artist

To become an artist, all you need is a knowledge of the materials and tools you want to work with. Using metal, you can create sculptures, signs, and other pieces of art for clients all around the world.

Metal artists are usually in business on their own, so understanding social media and digital marketing is also a plus for this career path.

For all of your metal cutting needs, you can invest in a horizontal or vertical bandsaw as well as a few vises. Check out our product page for more metalworking machines that make the process of creating art so much easier.

#6 - Metal Finisher

Becoming a metal finisher involves understanding the properties of certain metals and what is required to get the desired finished look. Texturizing and finishing is an entire skill set in metalworking. It takes a lot of practice to get it right, and metal finishing is highly sought after in the metalworking industry.

A great that many metal finishers work closely with is the Dake Belt Grinder. With a 4 HP motor and a grinding speed of 6,600 fpm, this handy power tool is used to texturize various types of metal. It can be fitted with different belts to achieve unique finishes, and it comes with a Plexiglass shield to prevent the metal piece from moving during the finishing process.

It is adjustable to suit the operator's height as well. If you are considering a career as a metal finisher, this is the tool to have on every job.

-1.jpg?width=1200&height=525&name=DAKE003_%20Logos_Red%20(002)-1.jpg)

.jpg)