In a metalworking shop, fewer things yield more valuable benefits than preventive maintenance on the equipment.

Many shops, however, think of the bandsaw as "support equipment" and give less attention to its maintenance needs. That's a mistake since regular maintenance on your bandsaw will translate into lower costs, higher productivity, and a lot less frustration.

With the help of preventive maintenance, machine shops, fabricators, and welding shops will benefit from straighter, smoother cuts that will prevent wasted material and reworks. Well maintained saws are efficient and safe and can boost a shop's reputation.

Every bandsaw in the plant should have a maintenance schedule. The schedule should be on a clipboard hanging near the machine and have lines for recording the date and type of maintenance.

It's essential to be consistent with the maintenance. The inspections and the maintenance itself typically won't take more than a half-hour—a small amount of time that will pay off by increasing the life of the machine and the blade.

Here are the critical areas that require special attention:

Get the maximum life from your blade

Make sure you check the working parts of your bandsaw frequently. Making the needed adjustments will ensure that the blade is cutting properly and could prevent damage to the machine. Here is what to look for:

- Inspect the band wheels—surfaces, flanges, and fluid grooves--whenever you change the blade: If the wheel looks out of round or cracked, replace it, or the blades could break more frequently. Clean the grooves if they are packed with chips, so the blade makes good contact with the wheel's surface.

- Check the blade tension at every blade change, or even more often: If you are sawing for an extended period, your blade can heat up and expand, in which case the tensioners take up the slack. Sometimes, when the blade cools, there is too much tension and extra pressure on the wheel bearing. On the other hand, not enough tension will cause crooked cuts from poor tracking. Check the tension every time you subject the blade to continuous work.

- Examine the band guides at least every six months: The band guides are a critical component of the bandsaw, and you need to install them according to the manufacturer's instructions. Worn or chipped side guides cause crooked cuts and shorter blade life. Rotate or replace them as soon as you spot wear. The backup guides cause the same issues if they are worn or broken, so replace them when needed.

- Check the band wheel bearings twice a year: You will be looking for abnormal wheel movement, causing the guides to wear prematurely and resulting in blade failure and damage to the bandsaw.

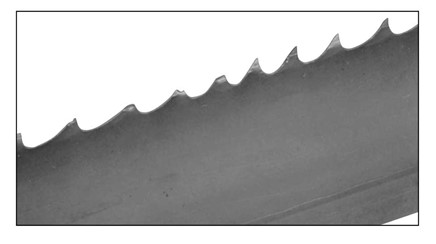

With the proper care, you could prevent problems with blade failure (below).

Photo Credit: Oregon Industrial

Take care of the vises

Clean the chips from the vise jaws every time you use the saw. At least twice a year, check the jaws for wear. Repair, replace, and adjust them as needed since too much wear will result in crooked saw cuts. Check the alignment of the stationary jaw to the blade. It should be at 90 degrees to ensure a straight cut.

The photo (below) shows a horizontal bandsaw with its vise jaws aligned to the blade correctly.

Photo Credit: Cutting Tool Engineering

Pay attention to the hydraulics

If your feed system and vise run off a hydraulic system, you need to check the oil level often. Low levels can result in air getting into the lines, and anything that depends on the hydraulics won't work correctly. If sediment builds up in the oil reservoir, it could start blocking the line and filter, causing low pressure.

Every six months, change the hydraulic filters and remove the metallic particles from the magnetic plug in the reservoir. And once a year, change the hydraulic fluid and clean the fluid strainer.

Keep the coolant tank filled and fresh

Coolant keeps the blade cool and lubricates the cutting area.

Photo Credit: Blade Serpent

Replace the coolant and clean the filters regularly. You will likely be mixing cutting oil with water to create the coolant, so it's crucial to have the correct ratio between the two.

Check the manufacturer's manual to find out that ratio, then use a refractometer to confirm it. With an incorrect balance in the coolant, the workpieces could overheat, and your blade life might be shorter.

A word of caution: Don't try to save money by using water alone. You could end up with corrosion, a rough cutting finish, or bacteria, costing you even more money.

Inspect the drives every six months

While you can do the following checks in-house, you might want to consider a professional if you must replace any items.

Visually inspect all of the bearings, and check for oil leaks. Replace defective bearings and seals before they lead to significant damage to the drive system.

If you have a gear-driven saw, check the drive wheel for excess play. Too much play often indicates worn gears. If you don't replace them, the machine may develop serious driveshaft and transmission problems.

Also, check the pulleys for proper alignment, tension, and wear. Incorrect alignment or tension might cause extra belt wear and bearing failure. If possible, adjust the pulleys, or replace them if they are damaged.

Check the belts every six months

If any of the belts have stretched or show excessive wear and cracks, your saw's performance could be inconsistent, and it will likely reduce the life of your belts. Replace the belts when you see that they are worn out, rather than waiting until they break during a cut.

Taking these simple maintenance steps can increase the life of your bandsaw and help you get the most out of your saw blades. Metalworking shops that follow the prescribed maintenance procedures will also improve cutting efficiency, quality, and safety. Preventive maintenance might cost a bit, but it can pay some substantial long-term dividends.

Check out our lineup of high-quality bandsaws

Dake offers a line of both vertical and horizontal metalworking bandsaws that are built to last. The Trademaster vertical bandsaw comes with a power feed and a tilt table, while the Model JH10W3 horizontal bandsaw offers features that include four-speed drive, three-point suspension, and centralized controls.

To find out more, fill out our contact form, call us at 1-800-937-3253, or email us.

-1.jpg?width=1200&height=525&name=DAKE003_%20Logos_Red%20(002)-1.jpg)

.jpg)