If you work in manufacturing, you have likely seen a few hydraulic presses. Fabricators use them in all types of operations, such as bending, forming, and pressing. Recyclers use them to crush cars, and machine shops press bearings and do stamping with them. A hydraulic press can be indispensable in most industrial environments.

The hydraulic press is made up of two cylinders that are connected. While both cylinders contain hydraulic fluid, one cylinder is larger than the other. The larger cylinder is called the ram, and the smaller one is known as the plunger.

Liquids are hard to compress, making them ideal in a hydraulic press. The hydraulic press works by exerting a small amount of force onto the plunger, pressing the fluid below. The pressure is distributed evenly and, in turn, raises the ram. The pressure between the plunger and the ram works to crush anything placed between them.

While those who work with hydraulic presses may understand them thoroughly, those outside the industry might find some of the terminology confusing. Although it might not be necessary to comprehend every term associated with hydraulic presses (and there are a lot of them!), here are some of the standard hydraulic press terminologies that everyone should know:

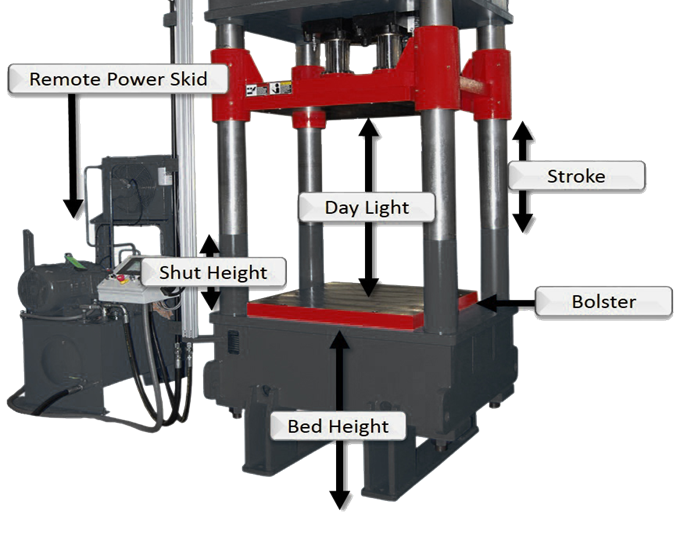

Basic Hydraulic Press Terminology (Photo Credit: Beckwood)

Bed: A flat, stationary surface that supports the lower bolster or a die

Bolster: A removable plate that serves as the working surface of a press. The bolster is typically bolted to the bed. Tooling is attached to the bolster, which can have holding features such as T-slots and tapped holes.

Bed height: The distance from the floor to the top of the bed

Daylight: The distance between the bed bolster and the ram bolster when the ram is fully retracted. It is also referred to as “open height.”

Shut height: The distance between the bed bolster and the ram bolster when the ram is fully extended. This is commonly called “closed height.”

Stroke: The total distance the ram can travel from full extension to full retraction.

Tonnage: The maximum amount of force that the press can apply. It is usually stated in US tons.

Dake’s Model Force 150 Hydraulic Press (Photo Credit: Dake Corp.)

Hydraulic power unit (HPU): The power unit applies the pressure to drive motors, cylinders, and other parts of a hydraulic system. These units use multi-stage pressurization networks to move fluid and often include temperature control devices. HPUs are typically either skid-mounted or crown-mounted.

Cylinder: The primary actuator of a hydraulic press converts hydraulic pressure into linear movement creating force. Many high-quality hydraulic presses, such as the Dake Three Phase Dura-Press (above), have a double-acting cylinder design to ensure smooth operation and a tight seal.

Ram speed: Measured in inches per minute (IPM), the ram speed indicates how fast the ram moves from an open to a closed position. The ram typically approaches the workpiece rapidly and automatically slows upon contact before retracting at a faster speed.

Check out our complete line of hydraulic presses

Our heavy-duty hydraulic presses make quick work of your straightening, fabrication, quality control, maintenance, product testing, bending, forming, punching, assembly, and shearing tasks. Dake has been manufacturing H-frame hydraulic presses since the 1940s so that you can trust their quality and experience.

And if you have additional questions about hydraulic press terminology (or anything else, for that matter), talk to one of our experts.

To find out more, fill out our contact form, call us at 1-800-937-3253, or email us.

-1.jpg?width=1200&height=525&name=DAKE003_%20Logos_Red%20(002)-1.jpg)