It’s not surprising that so many manufacturing companies have turned to hydraulic presses over the last few decades. These versatile machines have surpassed the traditional mechanical press as the more popular option, especially in production press work. While the mechanical press employs a rack and pinion and crankshaft to provide tonnage, hydraulic presses utilize a pump and cylinder, along with hydraulic oil, to create a substantial compressive force.

Hydraulic presses speak for themselves, making the decision to own one relatively simple. But choosing the right press for your application is critical, so identifying a press’s capabilities and matching them to your specific needs is an essential first step.

Here are a few things to consider:

How will you use your hydraulic press?

Since each application has a set of requirements, you should think about the role a hydraulic press will play in your shop. Write down a list of tasks you hope to accomplish with your press. Today’s hydraulic presses have an extensive range of capabilities, including:

- Assembling parts such as bearings and electrical switches

- Deep drawing of products such as fire extinguishers and fan housings

- Coining, a cold-working squeezing operation requiring high tonnage

- Forming, which changes the shape of a metal piece

- Embossing or creating imprinted designs in sheet material using dies

- Stamping or transforming the shape of a flat piece of material

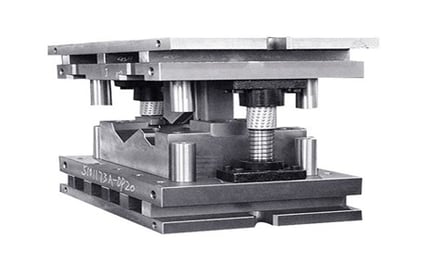

A Sheet Metal Stamping Die Used in a Hydraulic Press

Photo Credit: Stamping Simulations

- Trimming, typically a secondary operation to trim or shear a previously formed piece

- Press fitting or assembling parts with an interference fit

This list is far from exhaustive, so you will need to determine your specific applications.

How much tonnage will you need?

After you determine how you will use your press, the next question is how much tonnage will be needed for your work. If you move from a mechanical press to a hydraulic press, the tonnage requirements will stay the same. You will only need to know the maximum tonnage since most hydraulic presses can be adjusted downward depending on the task.

Selecting the required tonnage is not an exact science (some say it’s little more than guesswork), but it will depend on factors such as the perimeter of the punch, the shear strength of the material, and the material’s thickness. While there are formulas for calculating tonnage, your best bet is to select an experienced vendor with engineering expertise that will partner with you and assist you in the decision-making process.

The professionals at Dake can answer your questions and help you choose the right hydraulic press and tonnage for your applications.

What type of press is best suited for my work?

After you have decided its uses and tonnage, you can choose the type of press suited for your operation. While you will find numerous types of hydraulic presses, you will probably end up deciding between two primary types: the powerful H-Frame presses and the smaller open frame presses, also known as C-Frame. Both are used in the metalworking industry.

H-Frame presses, sometimes called four-post or four-column presses, are much larger than C-Frame presses and typically more powerful. These presses have a reputation for better accuracy and power because of their symmetrical design and equal pressure distribution. As their name suggests, these presses have four posts that guide the pressing plate to the table and tooling.

Dake’s Elec-draulic II is an H-Frame 75-Ton Dual-Acting Press

Some of the outstanding characteristics of the H-Frame include versatility, flexibility, ease of operation, smooth transitions, fast setup, simple maintenance, and reasonable prices. They are highly recommended for shops with applications where pressure is a top consideration.

C-Frame presses take up minimal floor space and have three-sided access. They are used by manufacturing operations with limited space, do not require as much power, and do not work on larger parts.

Do I need tooling and accessories?

Many hydraulic presses come with standard equipment such as a table hoist, flat-ram and v-ram noses, and stroke indicators. There may also be controls and features to improve productivity and save money. Once again, an experienced vendor will become your partner and help you choose the right tooling and accessories to match your unique operation.

Check out the Dake family of hydraulic presses

Our heavy-duty H-Frame hydraulic presses are ideal for manufacturers and fabricators that perform straightening, bending, forming, pressing, embossing, maintenance, punching, assembly, and shearing work. Dake has been manufacturing H-frame hydraulic presses since the 1940s. You can trust their advice and the quality of their equipment!

To find out more, fill out our contact form, call us at 1-800-937-3253, or email us.

-1.jpg?width=1200&height=525&name=DAKE003_%20Logos_Red%20(002)-1.jpg)

.jpg)