Walk into any fabrication or machine shop, and you're likely to see an arbor press. It will either be attached to a workbench or set on a pedestal in some out-of-the-way corner. No, these versatile presses are not going to be the centerpiece of a manufacturing workplace. They are part of the "support equipment" that is standard in these shops.

But just because they don't get the attention of all those CNC machine tools—or their famous cousin, the hydraulic press—doesn't mean they don't play an important role. These small hand-operated presses are at home in an industrial setting or a home workshop.

They can handle all sorts of press-fit tasks: installing bearings and bushings, pressing dowels, and roll pins. They can straighten or bend metal, punch holes in leather, or even crush aluminum cans for recycling!

They are ideal for broaching keyways, forming small sheet metal parts, light riveting, staking, reloading bullets and shells, making jewelry, and compressing springs for assembly. Whether you work out of your garage or a dedicated workshop, you will probably find multiple uses for an arbor press.

Broaching a Keyway with an Arbor Press (Photo Credit: HMS Makina)

How does an arbor press work?

A relatively compact machine, the arbor press features various components working together to produce a press. Those components include a ram, recoil spring, lever arm, arm stop, and base. You place the item you want to press on the base and pull down the lever arm. This action turns an internal pinion gear rotating along the toothed rack of the ram. The rack and pinion transform rotary motion into straight-line motion, forcing the ram downward onto the workpiece.

Look for the tonnage rating (usually 1 to 12 tons) to determine the maximum pressure the arbor press can safely exert.

Types of Arbor Presses

Since there are four types of arbor presses, you need to decide how you're going to use your press before running out and buying one. Here is a run-down of each type to help you determine which one will be the best fit for you:

Single-Lever Arbor Press

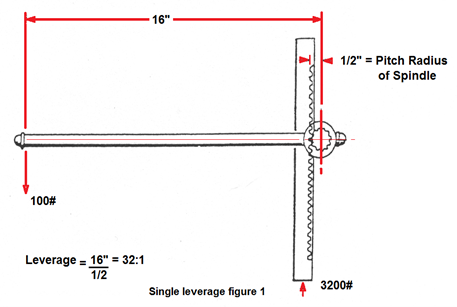

The single-lever press is the most popular arbor press. It has few moving parts and is typically rated from 1 to 3 tons. Perfect for a do-it-yourselfer or hobbyist, a single-lever press easy to use and affordable. Just pull the lever arm to start pressing.

A sketch of the Dake single-lever arbor press is shown above. The leverage is the ratio of the distance from the end of the handle to the center of the spindle divided by the pitch radius of the spindle pinion, or: 16" (handle length) divided by 1/2" (spindle pitch radius) = 32:1 ratio.

Ratchet Lever Arbor Press

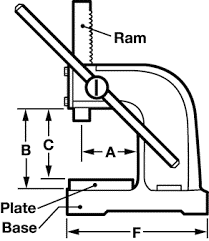

This arbor press ratchets down the ram with each pull of the handle, which is why it's called a ratchet-lever press. It comes with a handwheel to adjust the ram's position and a spring-operated brake to keep the ram in place. When shopping for an arbor press, consider the size of the part you will be pressing into and choose an appropriate throat depth (see below).

Dimension "A" refers to the arbor press's throat depth. Dake Ratchet-Lever Arbor Presses

come in a range of depths from 7" to 17 ½".

Compound Lever Arbor Press

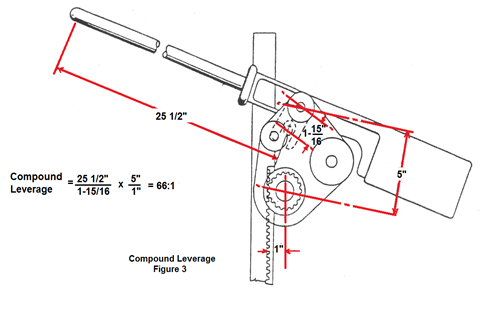

Designed for heavier applications, the compound leverage press has a mechanism that allows more significant pressure application (up to 12 tons) with a minimum amount of effort. These are typically regarded as professional-grade arbor presses instead of a DIY tool. In most models, a sliding pin converts the press from a compound to a single-lever press.

The compound press increases the leverage when the long sliding pin is engaged in the lever weight. Any force to the end of the handle is multiplied and added to the compound at the lever-weight pin.

The ratio by which the force is multiplied is the distance from the end of the handle to the centerline of the long sliding pin divided by the distance between the long sliding pin and lever weight pin (see the diagram below).

The compound then multiplies the force applied to it and, utilizing the pawl, transfers it to the spindle and then to the ram.

Diagram of the Compound-Lever Arbor Press

(Note: Sliding pin would be engaged with the slot in the lever weight)

Air Arbor Press

Pneumatic arbor presses are another versatile option for forming, crimping, broaching, stamping, electronics, and die work. Typically available in one and two-ton capacities, the highest quality models feature double-acting rams, chrome-plated piston rods, and two-hand safety controls.

The air arbor press allows for easy adjustments on air pressure, stroke, and ram speed. And threaded rod ends mean that changing tooling and nose pieces are quick and straightforward.

Check out this short video to find out how easy pressing bearings or bushings can be with an air arbor press.

We have a wide range of arbor presses to meet your needs

We make 17 different arbor presses in single-lever, ratchet-lever, and compound-lever designs, along with our air arbor presses, available in 1,000 and 2,000 lbs. capacities. Whether you're looking to add an arbor press to your professional shop or your home workshop, Dake can provide what you need.

To get more information, fill out our contact form, call us at 1-800-937-3253, or email us.

-1.jpg?width=1200&height=525&name=DAKE003_%20Logos_Red%20(002)-1.jpg)