Here at Dake, we offer both vertical and horizontal bandsaws to suit your metal cutting needs.

Whichever model you choose, you’ll need to break it in before you can get the best results. Properly breaking-in a new bandsaw machine will increase its overall lifespan.

This means that it will work efficiently for a lot longer than if you skipped this crucial first step entirely. In this post, our experts will share with you how to break-in a brand new bandsaw blade.

Breaking-In the Blade Process

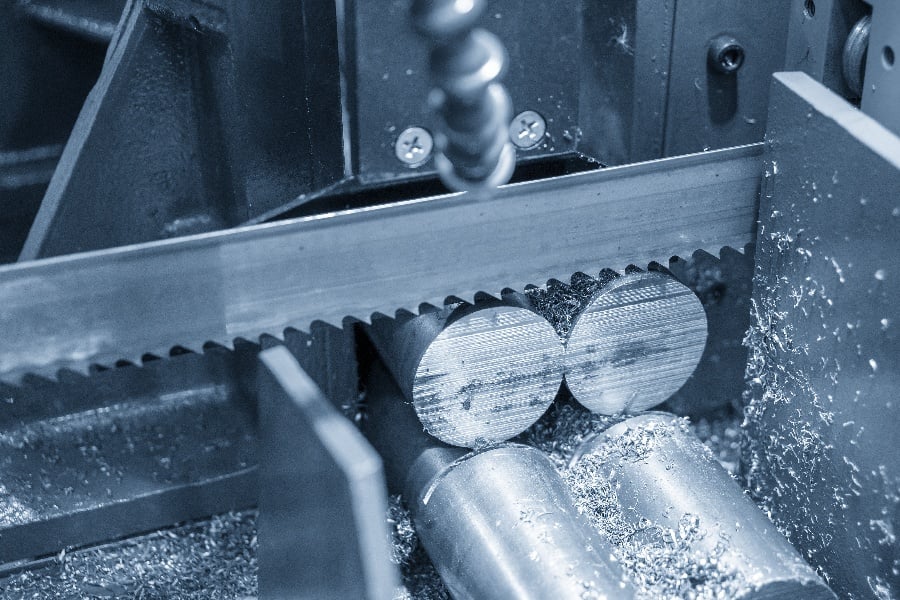

New bandsaw blades have razor sharp edges on the teeth. While that might sound like a good thing, these ultra-sharp teeth can be easily broken off or chipped if you skip the break-in process.

Think of it this way. What happens when you sharpen a pencil to an ultra-fine point and then try to write with it? The lead snaps almost immediately.

However, it doesn’t break off from the wooden section of the pencil. It breaks on the tip and leaves a jagged edge that will give you funny looking letters if you try to write with it. At this point, you need to rub the jagged end of the pencil on some paper to smooth it. Then, you can use it to write until it needs to be sharpened again.

The same basic principle applies to bandsaw blades. Instead of jumping to using it, you need to gradually break it in by slowly increasing the feed pressure to smooth the teeth over without snapping the points off. This will result in a fine, evenly honed radius on the leading edge of each tooth.

Once the blade is broken in, you will be able to cut metal materials easily by offering the proper support to the teeth. Cutting metal is hard work. Be nice to your machines, and they will work more efficiently for you.

Blade Basics

If you have read our recent blog post about how to choose the right bandsaw blade, then you already know that there are many various blades to pick from. Typically classified by their teeth, bandsaw blades may require different breaking-in techniques to get the best results.

As a quick recap, let’s go over the basics of bandsaw blade teeth. The first thing you need to look at is the number of teeth per inch (TPI). This will determine the appropriate feed rate and the type of finish you should expect. A higher number of TPI will result in a smooth, fine cut at a slower feed rate. Meanwhile, fewer TPI will result in a rough cut at a faster feed rate.

There are three types of bandsaw blades includes regular-tooth, hook-tooth, and skip-tooth blades. Regular-tooth blades are the most common because of their deep gullets and straight teeth. They are ideal for cutting sheet metal.

Hook-tooth blades also feature deep gullets, but their teeth are widely-spaced and best suited for quick, rough cuts. Finally, skip-tooth blades are designed with shallow gullets and sharply-angled teeth that are spaced out. This type of blade is best suited for cutting nonferrous metal.

Break-In Process

The break-in process will vary depending on the type of bandsaw blade you are working with and the kind of metal material you wish to cut.

To start the process, run the bandsaw machine at the normal surface feet per minute (SFPM) speed. If you are cutting a soft metal such as aluminum or carbon steel, you should adjust the SFPM down by 50% for the first 50- to 100-square-inches of cutting. Then you can slowly increase the SFPM speed until you reach 100%.

If you are working with hard metals such as nickel-based alloys, steel, or stainless steel, then you will need to adjust the SFPM speed down to only 75% of the normal sawing rate for the first 25- to 75-square-inches. At that point, you can begin to slowly increase the SFPM speed until you reach 100%.

Pro Tip: As you increase the SFPM speed, make sure that there are no vibrations. Too much rattling can ruin your piece and cause premature wear to the blade.

If you follow the break-in process as laid out, then your bandsaw blade will give you straighter, faster cuts. You also won’t need to replace the blade as often.

Should You Skip the Break-In Process?

After reading about how important it is to break-in a bandsaw blade, you may be wondering why anyone would skip this step altogether. The main reason why some metalworkers don’t break-in their blades is that they are trying to rush the process to make their products so as to get it in the market sooner.

However, skipping the break-in process will not result in higher profit margins. It will actually end up costing you more to replace the blades more often.

If the teeth on the blade keep breaking because you haven’t broken them in properly, you will spend more time and money replacing the blades. A better goal to have would be to extend the lifespan of your blades as long as you can. This minimizes the cost per cut and improves the overall profitability of your metalworking shop.

Another way to extend the life expectancy of a bandsaw blade is to ensure proper care and regular maintenance. We have a great blog post about machine maintenance that you can take a look at here.

At the end of the day, treating your blades gently and breaking them in will result in better cuts and a longer lifespan.

Get in Touch with Dake

Our experts here at Dake specialize in metalworking machines. We manufacture all of our machines right here in our facility, and can even customize machines to suit your specific needs. If you have any questions, we are more than happy to help. To learn more about our products or to request a customization, get in touch with our team today.

-1.jpg?width=1200&height=525&name=DAKE003_%20Logos_Red%20(002)-1.jpg)

.jpg)